The current position:Home > Information dynamic

> Industry Trends

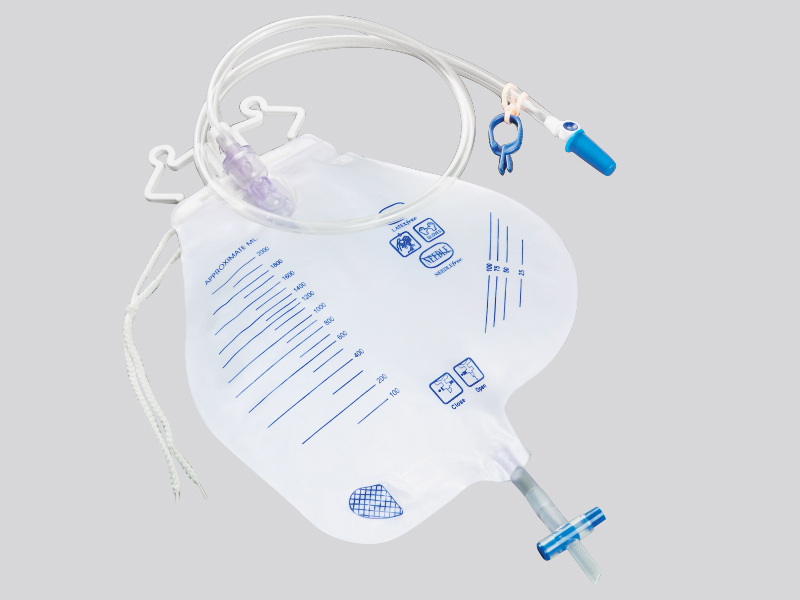

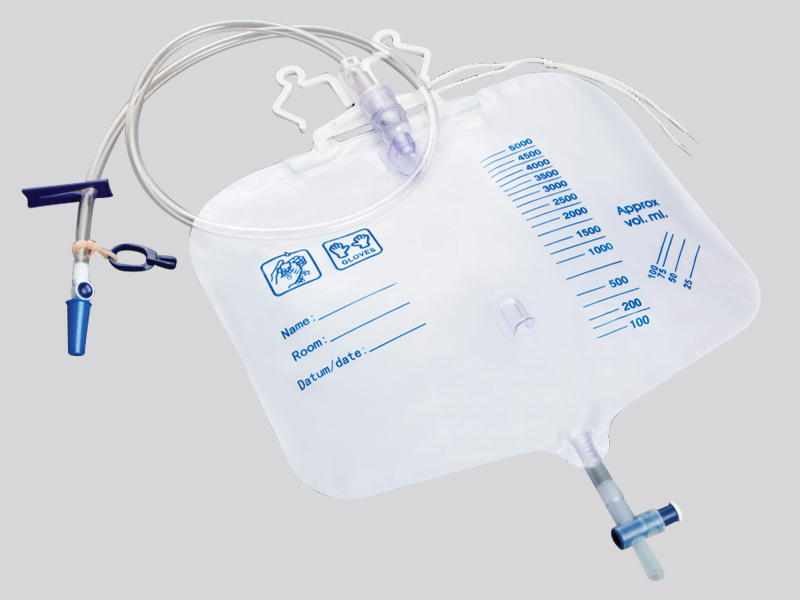

What are the materials of disposable feeding bags

source:m.zzykcz.com | Release time:2025年10月27日1、 Core main material (part in contact with nutrient solution)

This is the most critical material part of the feeding bag, which directly determines its safety and requires good biocompatibility and resistance to nutrient solution erosion.

1. Polyvinyl chloride (PVC)

Features: Good flexibility, high transparency, easy to observe the remaining amount and status of nutrient solution; Low cost and widely used.

Attention: Traditional PVC materials may contain plasticizers (such as DEHP), and there is a risk of plasticizer migration when exposed to high-fat nutrient solutions for a long time. At present, environmentally friendly PVC without DEHP is widely used in the medical field, or gradually replaced by other materials, especially suitable for short-term, non high fat nutrient feeding scenarios.

2. Polyethylene (PE)/Low Density Polyethylene (LDPE)

Characteristics: Good chemical stability, no risk of plasticizers, safe and non-toxic, good compatibility with various nutrient solutions (including fat emulsions); Soft texture, excellent low-temperature resistance, suitable for refrigerated nutrient solutions.

Application scenario: It is currently one of the mainstream materials for disposable feeding bags, especially suitable for long-term enteral nutrition feeding, as well as pediatric and elderly patients with high safety requirements.

3. Polypropylene (PP)

Characteristics: High temperature resistance better than PE (can withstand high temperatures of around 100 ℃), and some can withstand wet heat sterilization; Slightly high mechanical strength, good transparency, strong chemical stability, non-toxic, and good compatibility with nutrient solutions.

Application scenario: It is commonly used for feeding bags that require heating infusion or have certain requirements for material strength. It is also commonly used as a base material for composite films to enhance the stability of the bag structure.

4. Multilayer composite film

Characteristics: Composed of two or more materials (such as PE/PP, PE/EVOH, PP/PET, etc.), combining the advantages of different materials. For example, the inner layer is made of PE to ensure safety and compatibility, the outer layer is made of PET or PP to enhance strength and puncture resistance, and the middle layer is made of EVOH (ethylene vinyl alcohol copolymer) to enhance barrier properties and prevent nutrient solution oxidation and deterioration.

Application scenario: Suitable for nutrient solution packaging that requires long-term storage and high barrier properties, or special nutrient solution feeding bags containing easily oxidizable ingredients such as vitamins.

2、 Material of supporting components

The connecting pipes, joints, valves and other supporting components of the feeding bag need to be coordinated with the main material to ensure overall safety and functional implementation.

1. Connecting pipes and joints

We often use medical grade PVC (without DEHP), PE or PP materials, which have good flexibility and compression resistance, ensuring smooth delivery of nutrient solution and avoiding impurities caused by material aging and shedding.

Some precision joints (such as the interface connected to the feeding pump) may use ABS resin, which has high mechanical strength, accurate dimensional accuracy, ensures connection sealing, and prevents liquid leakage.

2. Flow control component

Dripping bucket: usually made of transparent PVC or PP material, easy to observe the dripping speed, the material needs to be clear and transparent, without impurities.

Flow regulator (such as Robert clamp): It is often made of polypropylene (PP) or polyethylene (PE), which has certain elasticity and strength, and can control the liquid flow rate correctly by squeezing the pipeline. It is also not easy to deform and fail after long-term use.

3. Seals and ports

The sealing parts of the bag body, such as the dosing port and infusion port, are often sealed with medical grade rubber plugs or silicone plugs, which have good sealing performance and excellent self sealing performance after puncture, preventing nutrient leakage and external pollution; Some port covers are made of PP material, which combines sealing and easy opening.

Cn

Cn En

En WeChat ID:

WeChat ID:

Contact us

Contact us

Add WeChat

Add WeChat

Telephone

Telephone